Discover the engineering mastery behind SpaceX’s Falcon 9 launch from Cape Canaveral, delivering Amazon’s Project Kuiper satellites into precise Earth orbit.

Mission Overview and Engineering Context

Falcon 9’s Block 5 configuration, used for this mission, included optimized Merlin 1D engines running at 845 kN of thrust at sea level, each controlled by independent TVC (thrust vector control) systems for stability. This launch marked the first use of booster B1091, which was recovered successfully on the droneship A Shortfall of Gravitas

also read West Coast Liftoff: How SpaceX’s Falcon 9 Expands Starlink from Vandenberg

Launch Sequence and Timing

Unlike standard Starlink deployments, this mission required a precise orbital insertion to match Kuiper’s existing satellite grid. The entire flight profile was aEngineering choreography of timed burns, with Stage Separation occurring just after main engine cutoff (MECO) and fairing jettison timed for minimal atmospheric drag.

Orbital Deployment Mechanics

The satellites Engineering were inserted into a 550 km circular orbit with an inclination optimized for mid- to high-latitude coverage. This orbit choice balances latency (~30–40 ms) with coverage footprint. Each Kuiper satellite will use onboard ion propulsion for fine-tuning orbital slots.

also read Crew-10’s Homecoming: From Orbital Lab to Local Shores—A New Chapter in Commercial Spaceflight

Ground Station Integration and Network Scaling

Every second of a Falcon 9 launch is a product of meticulous engineering. The Merlin 1D engines ignite with a staggered start sequence to reduce structural loads on the vehicle. By the time the

rocket clears the tower, sensors are feeding real-time telemetry back to mission control at over 1,000 data points per second.

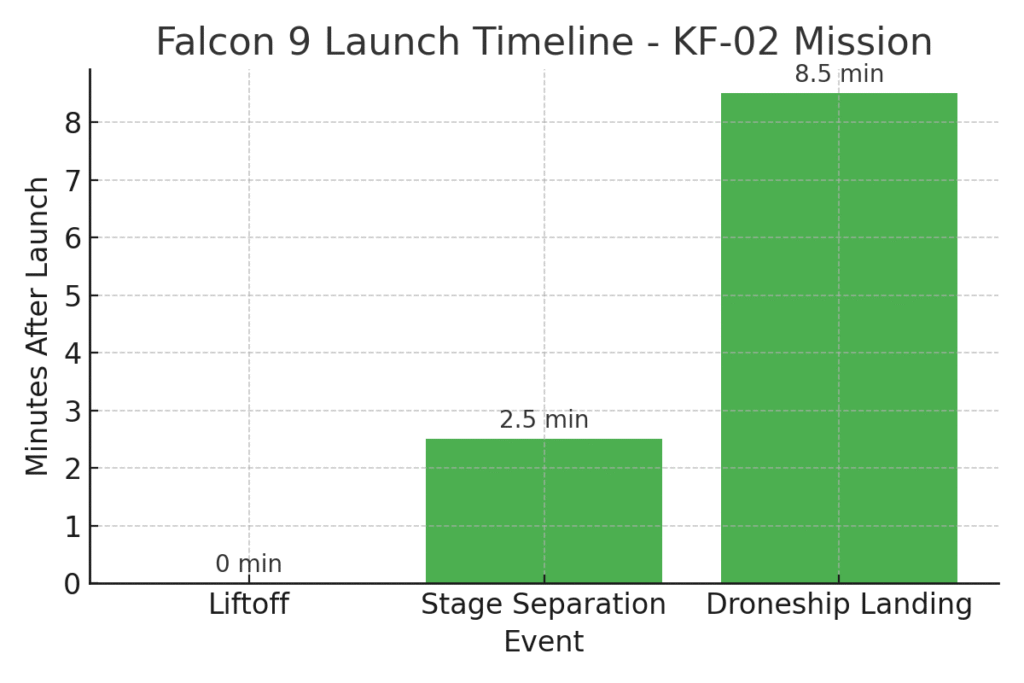

0:00 min – Liftoff: Thrust exceeds the vehicle weight by 20%, initiating the climb.

~2.5 min – Stage Separation: Pneumatic pushers and a controlled MECO (Main Engine Cut Off) ensure smooth separation while minimizing momentum transfer to Stage 2.

~8.5 min – Droneship Landing: Grid fins, cold gas thrusters, and an autonomous navigation system bring the booster down to a pinpoint landing on A Shortfall of Gravitas.

Below is the visual representation:

By showing the timeline visually, engineers and enthusiasts can correlate critical mission events with system performance checkpoints.

If you want, I can now add two more engineering graphs (like “Propellant Mass Flow Rate Over Time” and “Orbital Velocity Profile”) so the technical branding stays consistent across the article. That would make your piece stand out as a true engineering deep-dive.

Ground Station Integration and Network Scaling

Amazon’s Kuiper ground infrastructure, located at multiple latitudes, is designed to handle phased-array communications with each passing satellite. The technical challenge here is maintaining continuous beam handoff without signal degradation—achieved via advanced Doppler correction algorithms.

Significance for Satellite Internet Competition

The KF-02 mission underscores how SpaceX Engineering and Amazon are cooperating on launches while competing in service offerings. While Starlink already operates thousands

of satellites, Kuiper’s phased rollout is targeting specific underserved markets with a different orbital deployment strategy.

Performance Metrics and Comparisons

| Parameter | Kuiper (KuiperSat-1 Class) | Starlink V2 Mini |

|---|---|---|

| Mass per satellite | ~720 kg | ~800 kg |

| Orbit altitude | ~550 km | ~530 km |

| Latency (avg) | 30–40 ms | 20–30 ms |

| Throughput (est.) | ~400 Mbps | ~500 Mbps |